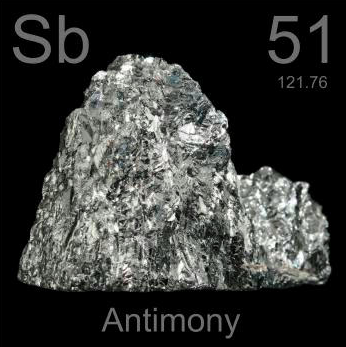

Antimony (Sb) is an element that is blended in with metals such as lead to create different alloys. In lead-based alloys, antimony is added in the range of 1/2 percent to 12 percent and most commonly it is used in a range of 1/2 percent to 6 percent antimony and the balance of the alloy is lead or tin.

Antimony (Sb) is an element that is blended in with metals such as lead to create different alloys. In lead-based alloys, antimony is added in the range of 1/2 percent to 12 percent and most commonly it is used in a range of 1/2 percent to 6 percent antimony and the balance of the alloy is lead or tin.

The use of a little antimony in castings will help material flow so it acts to improve the feed into a part compared to pure lead. In machined or structural products, antimony adds rigidity to the design. Pure lead acts like butter on a warm day and the use of antimony will stiffen the alloy to allow machining to take place and keep the part from moving like that of pure lead. The same holds true for the use of antimony in structural parts, 6 percent of antimony will really strengthen the part and, when some tin is blended as well, this can help based on your design.

So what does this do to the density? Pure lead has a density of .41 pounds per cubic inch. Six percent antimonial lead has a density of .393 pounds per cubic inch, which is a loss of .0028 per percentage point of antimony. For a little loss in density, the mechanical properties gained are significant.

Based on alloy and product type, not all forms of metal can be blended with different alloys of antimony. Castings can be made from nearly any alloy while sheet and plate lead materials may require certain minimums. Six percent antimony is a standard in plate lead and cast product. Please contact Vulcan GMS to discuss your application and the available alloys.