BLOG

Vulcan GMS to sponsor USA Luge Slider Search on August 7

Vulcan Global Manufacturing Solutions is proud to announce its sponsorship of the USA Luge Slider Search event at the New Berlin Soap Box Derby Track. The event is free …

Vulcan GMS to sponsor USA Luge Slider Search on August 7 Read More »

The complexity of machining lead and lead-based products

Machining of lead-based products is difficult due to the soft nature of alloys. The pressure from the fixtures and cutting tools on lead-based parts can cause …

The complexity of machining lead and lead-based products Read More »

Vulcan GMS expands its facility for new offerings

Since our founding in 1978, Vulcan GMS has continued to expand and develop new capabilities. When we began, Vulcan was a mere 15,000 square foot facility …

Vulcan GMS expands its facility for new offerings Read More »

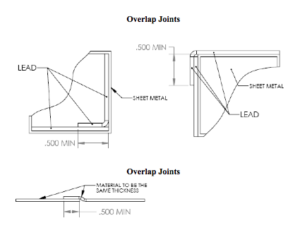

How to choose the best joint design for your radiation shielding project

Radiation shielding is a key benefit of lead and lead lining. There are five primary methods of shielding in joints between mating parts in a design. …

How to choose the best joint design for your radiation shielding project Read More »

The Technical Dictionary of Lead Casting Terms

While you may know generally what it is and understand a little bit about the process, lead casting truly is both a science and an art. …

Vulcan’s Yankes win Volunteer Spirit Award for USA luge

We are pleased to announce that Vulcan GMS owners Chuck Yanke and his wife Sandy Yanke have been awarded the 2015 Sam Venezia Volunteer Spirit …

Vulcan’s Yankes win Volunteer Spirit Award for USA luge Read More »

Vulcan’s process improvements don’t stop at the production floor

Back in 2008, Vulcan GMS began to see the benefits of paying its suppliers by ACH (Automated Clearing House) as a way to help control costs …

Vulcan’s process improvements don’t stop at the production floor Read More »

U.S. Luge dominates at Lake Placid in Viessmann World Cup Singles

In only the second sweep of a world cup event, the U.S. women’s luge singles team proudly earned their place on the podium. In the first …

U.S. Luge dominates at Lake Placid in Viessmann World Cup Singles Read More »

2015 Vulcan Golf Outing

Vulcan GMS held its annual golf outing this year at New Berlin Hill’s golf course and a good time was held by all. While no one …

Vulcan GMS wins Grainger Award in Manufacturing Excellence

Colin Powell once said, “There are no secrets to success. It is the result of preparation, hard work and learning from failure.” If something looks easy, …

Vulcan GMS wins Grainger Award in Manufacturing Excellence Read More »

Vulcan GMS Turns Ideas into Reality

(Note: Vulcan GMS employee Kevin Hartshorn also contributed to this article.) Taking a good idea and turning it into a truly innovative product can require a …

Vulcan GMS passes recertification of ISO 9001:2008 Standards

When Vulcan GMS first became ISO certified in 1999, we were the first of our kind in the United States to achieve that status. Vulcan is …

Vulcan GMS passes recertification of ISO 9001:2008 Standards Read More »